| Issue #57 • May/June, 1999 |

I am not ambidextrous. My wife, Judith, uses chopsticks with either hand or even both hands at once. She is ambidextrous. I can barely write with my right hand, much less my left. Even so, I use this ambidextrous method of sharpening my chainsaw, and can sharpen the chain in 10 minutes or less without removing the chain from the saw, while using only a chainsaw file and a homemade stand.

Here are the secrets to sharpening a saw without weird filing jigs, fixtures, or other expensive and time consuming mechanical aids.

Basic principles

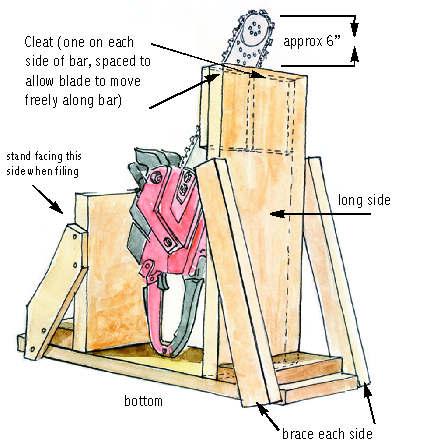

1. It is essential to look at what you are doing. You cannot, as I used to do, put the saw on the ground, kneel on the handle, and file away on the saw teeth and expect them to become sharp by the grace of a higher power. The homemade stand, shown in the illustrations, is designed to be used on a bench. It will place the saw chain where you can see what is happening to the teeth while you sharpen. The stand will also allow you to assume a comfortable position while you work on the saw. If you use reading glasses, put them on when you sharpen.

|

2.Orient the bar vertically. This is the most important purpose of the homemade stand. When the bar is vertical, gravity is your friend, and you can easily control the file position in the throat of the tooth. If you attempt to file the chain with the bar in a horizontal position, gravity drags the file downward into the throat, and you will miss the cutting edge entirely. Orienting the bar vertically is so important that once you learn this technique, you will henceforth lean the saw vertically upwards against a tree if the saw needs an emergency sharpening in the woods where the stand is not available.

3.Adjust the chain tension prior to sharpening. This will pull the teeth into the bar and prevent them from flopping back and forth while you sharpen. This will make your filing faster and far more precise.

4.Wear gloves while sharpening. When sharpening, you will grab the bar with one hand to stabilize it, and your other hand, which is doing the filing, will frequently be driven into the chain. Gloves make sharpening a much more safe and comfortable enterprise.

5.Keep a block of carpenter’s chalk in your chainsaw toolbox. When sharpening, use this to mark your starting point on the chain. It can be remarkably difficult to figure out when you have finished sharpening without this mark. You will also probably use the chalk to lay out cuts when you are using the saw.

6.When you begin to sharpen, allow the file to contact the tooth only in the forward (cutting) direction. Dragging the file back through the tooth will shorten file life considerably, will result in a poor tooth profile, and is at odds with the principle of watching what you are doing. After each tooth is finished, dust the filings out of the file teeth by brushing it across your pant leg. (I assume you are wearing work clothes if you are out there filing a chain saw). The file cuts more smoothly if it doesn’t have to jump over filings that are stuck on the file surface.

7.Sharpen the saw frequently. Once every one or two tank fillings is about right. If you sharpen at this interval, the saw will always be a pleasure to use and sharpening will go quickly. If you hit a rock, you might as well give it up and go sharpen the saw. A dull saw tends to wear the bar unevenly, so keeping the saw sharp will extend the bar life.

The homemade stand

The stand is nailed up from a few scraps of wood to loosely hold the saw in a vertical position. Make it of a size to hold your saw. The long vertical side should fall six inches or so below the top of the bar when the saw is placed in the stand. The two cleats on the long side of the stand that constrain the saw in the side to side direction are important. In order to position them, place the saw in the stand with the blade upright and mark the saw chain on either side where it contacts the long side of the stand. Leave a gap between the cleats that is wide enough to easily clear the saw teeth as you advance the chain to expose new teeth for sharpening.

Sharpening

Make sure that the saw’s off-on switch is turned off. It isn’t very likely that the saw could kick back while you are handling the chain, but I suppose it is possible. If the saw is electric, it should certainly be unplugged

Place the stand on a bench that is at a height so that the teeth in the center of the bar are at about eye level. Different chains require different file diameters so be sure that you have the correct file. I probably don’t need to mention that chain saw files are designed specifically for sharpening saw blades and are not the same as ordinary round files. For your first try, use a new file if you have one. This will show you how a good file should cut so that you will eventually know when to replace it. When the file is worn out, you can feel and also hear that it is not biting into the tooth material, and it won’t produce much in the way of filings.

|

Now to sharpen: Look at the saw teeth. You will notice, on newer chains, a diagonal line scribed across the rear part of the top outside surface of the tooth. The finished tooth profile as seen from the top of the tooth should be parallel to this line. If your saw chain does not have these scribed markings, you should draw lines across the back of the saw stand at the correct angle, and use these lines to guide your filing angle.

Stand in front of the short side of the stand so that you can see the teeth ascending on the top side of the bar. Pick a tooth that slopes upward to the left and mark it with chalk. You will sharpen this tooth first, and then sharpen all the similar teeth while advancing the chain through one full revolution. Then you will sharpen all the teeth with the opposite slope while advancing the chain through a second revolution.

Grasp the saw by the top of the bar with your left hand, and brace it firmly against the top of the stand and the right hand cleat. With your right hand, sharpen the tooth that you previously marked.

Unless the blade is rock damaged, sharpening a chain in good condition should take about four file strokes per tooth. Take your first stroke and watch what happens to the cutting edge of the tooth. The file must travel in a straight line that is parallel to the scribed line on the tooth. You must also pull the file slightly toward the cutting edge (which is toward you) to assure that the cutting edge rather than the bottom of the tooth throat is filed. If things are going well, you will see a slight “wire edge” form on the cutting edge which is the last fragment of metal breaking off when the tooth becomes sharp. When the tooth is finished, the entire cutting edge will be straight, parallel to the scribed line, and sharp enough to peel a chip off the top of your fingernail.

Now comes the ambidextrous part: When the left-upward sloping teeth are finished, it is time to repeat the process for the right-upward sloping teeth. The best way to do these teeth is to merely switch hands. Grasp the top of the saw blade with your right hand, and file with the left. This allows you to remain in a position directly in front of the saw where you can see what is happening to the tooth. Although I am strongly right-handed, I found this very easy to do the first time that I tried it, and now, the left-handed teeth actually seem to go faster than the right-handed ones.

This is a fast process. If your chain has 40 teeth, and you use 4 file strokes per tooth, sharpening requires only 160 file strokes.

Problems

If filing does not make the cutting edge parallel to the scribed line, it means that the file is not parallel to the scribed line. If you are rocking the file up and down (vertically), the cutting edge will become rounded. If the file is tipped front-to-back, the cutting edge will not remain parallel to the scribed line even though the file appears to be at the proper angle. (See the illustrations.)

Attempt to file the same amount off of each tooth. Count the number of strokes that you use and file the same number on each tooth. After a number of sharpenings, some of the teeth may become noticeably shorter than the others. To fix this, try to use fewer file strokes on these teeth for several sharpenings until the others catch up. If you wish to really true up the blade, you should locate and sharpen the smallest tooth, mark off its length on a scrap of wood, and use this as a gauge to file the remaining teeth.

If the saw has become rock damaged: Rock damage usually damages all the teeth on one side of the chain. Because of the way that I hold my saw when cutting near the ground, this usually seems to be the right handed teeth. The effect is usually to knock the point off all these teeth. To sharpen a rock damaged blade, I sharpen the blade using 10 or 12 file strokes per tooth, being especially careful to maintain the file alignment. This much filing may not completely restore the point on the tooth; however, the blade will usually cut reasonably well if the cutting edge is sharp. If the blade does not cut well, I sharpen it again and try it. I have never had to sharpen it more than twice. After a few more filings, the tooth point will be restored.

Rakers: Rakers are the projections that stick up between adjacent teeth to clear chips from the cut. Since the tops of the teeth slope backwards slightly, continued sharpening may drop the teeth so low that the blade rides on the rakers in the cut. This may prevent the teeth from biting even though they are perfectly sharp. If your saw chain has been filed a number of times and has reached a point where it just doesn’t seem to cut well, the rakers may be at fault.

Blade manufacturers sell filing guides for raker filing to drop the rakers the correct distance below the teeth. This is a simple metal channel that sits on top of the teeth. The raker to be filed protrudes through a hole in the channel, and it is filed with a flat file until it is flush with the top of the channel. I usually file the rakers three or four times during the life of the blade using one of these guides.

Do not over-do raker filing. If the rakers are too low, the saw “grabs,” becomes difficult to control when starting a cut, and is much more prone to kick back—a definitely dangerous condition. If you file the rakers too low, it will probably take several teeth filings before the teeth are low enough to correct the condition. Some one who knows more about chain saws than I do has told me that he never files the rakers because of the kick back problem. He feels that a really sharp blade will work even if the rakers are too high.

Try this method. Especially try using the saw stand. You will find that you can sharpen your saw with great confidence when you can actually see what is happening to the teeth. Inspect your current blade. You may discover that the teeth are all sharpened at odd angles and have irregular lengths. You will be able to true them up very quickly using the saw stand and a fresh file.

One of these days I’m going to show Judith how to do this and then I will really have a sharp saw.

|

Excellent. Absolutely loved reading and very helpful at the same time.