| Issue #18 • November/December, 1992 |

(For good background information for this article, the reader should read “Waterpower for personal use” in Issue No. 16 and “Design calculations for overshot waterwheels” in Issue No. 17. — Editor)

This installment deals with the classic overshot waterwheel.

This is the type most familiar to people where the water is introduced to the top of the wheel by a chute, known as a flume. In spite of the public impression that these machines are low technology, they were actually quite extensively studied by academicians. The first to study them was a Roman named Vetruvius, who wrote what is considered to be the earliest known engineering treatise. The work on waterwheels by Lazare Carnot’ in the early 1700s not only advanced fluid dynamics, but his study was the groundwork for the study of thermodynamics.

As we discussed in previous articles (Issues No. 16 and 17), the most important thing to determine when utilizing a waterwheel is “head”, or how far the water falls. This is important because it has a lot to do with the diameter of the wheel. Ideally, the wheel diameter should should be 90% of the “head”. For convenience we choose some even number, in feet, that is nearly 90%. Unless the wheel is unusually large, we choose a diameter equal to the “head” minus two feet. This two-foot difference will be the depth of our flume.

Spouting velocity

We will now return to the concept of “spouting velocity.” The water in the flume will flow to the end where it will fall two feet. We must determine how fast it is moving horizontally “and” vertically. You see, once it reaches the end of the flume, it begins to fall again, and gravity causes its downward speed to increase.

The answer is in the equation for spouting velocity, which is the equation that describes the speed of any falling mass: “velocity squared divided by two times a gravitational constant”, which is expressed mathematically as /2G. The gravitational constant (G) is 32.2. We used this last time to convert a velocity into a head. Now we will use it to convert a head into a velocity.

Instead of the /2G=Head, we will use the form: Head x 2G = velocity. It is the same equation; we re-arranged the terms to solve for a different variable.

If our water falls 2 feet the feet, the equation tells us the velocity will be 11.35 feet per second. At the same time, gravity is pulling the water down as it is moving horizontally.

Bucket curvature

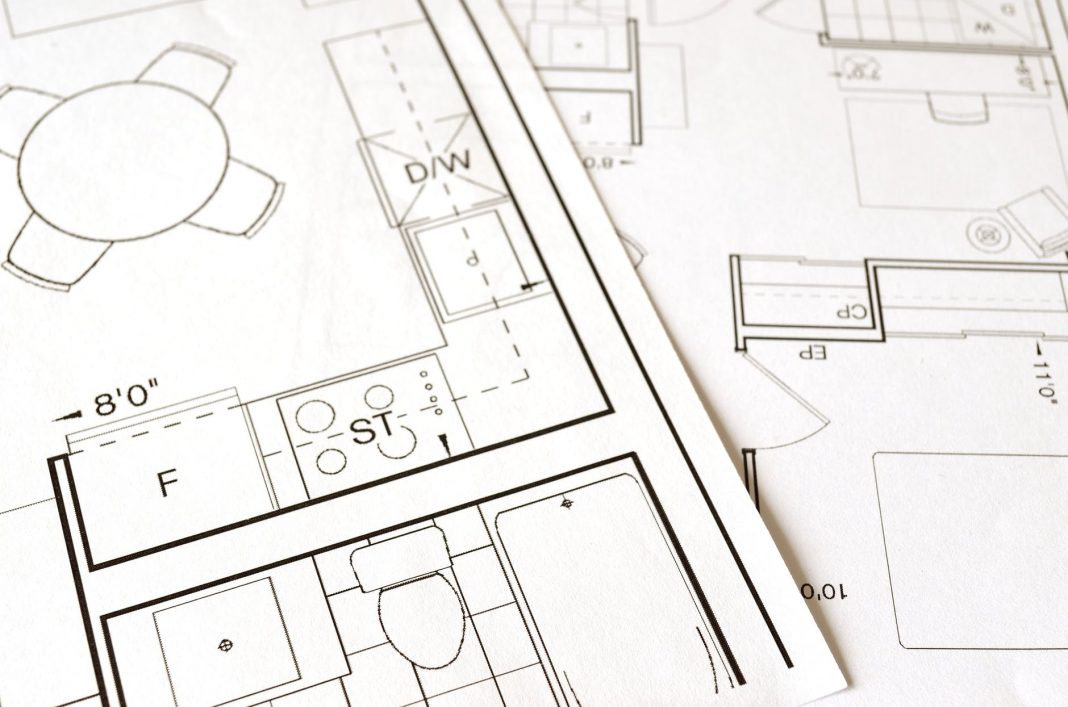

If we plot several points on a graph (see Figure 1) showing how the water travels horizontally as it leaves the flume, then vertically as gravity pulls on the water, we will get an arcing line. This line is very important. It will be the curvature of our buckets. By curving the buckets this way, the water enters smoothly and without splashing. It is then possible to make use of the velocity energy. Figure 1 is a graph of points for water leaving a two-foot flume.

Working diameter

The next step is to compute the working diameter. This is equal to the “total head” minus the depth of the flume. We will use a hypothetical head of 12 feet. This means our diameter will be 12’minus 2’= 10′. Now, multiply this number times “PI” (which is the mathematical constant equal to approximately 22/7 or 3.14) to get the working circumference. The answer will also be in feet: 31.4.

The number of buckets is relatively easy to determine. They should be approximately one foot apart, more or less, depending on the diameter. I recommend that it be an even number to simplify construction. Therefore, for our example we use 32 buckets. It is an even number and they will be almost one foot apart. The buckets should be around one foot deep.

Rotative speed

But how fast will it turn? The most efficient energy transfer occurs when the wheel speed is at 93% of the water speed. For our example, the spouting velocity is 11.35 feet per second. So 93% of that is around 10 feet per second, which is the same as 600 feet-per-minute. You divide this by the working circumference per revolution. This gives you an answer of 19 revolutions per minute. That is your best rotative speed.

As you can see, it is rather slow. That is why you will need a speed increasing system, as we said last issue.

Power considerations

The power you will get depends on the width. For our example, let’s assume you have a design flow of 50 cfs (cubic feet per second). When you divide this by the design speed of 10 feet per second, you see you need a bucket area of 5 square feet. If our buckets are 1 foot deep, the wheel should be 5 feet wide, “plus” one foot extra on each side to ventilate the buckets. As the water comes in, the air “must” get out.

One important detail: Put a one-inch diameter hole near the bottom of each bucket. This is to prevent them from sucking air when they are submerged. That can use up half of your power, while only a negligible amount of water leaks out. As I said last issue, power is equal to “flow” times “head” divided by 11.8. Therefore, we have a “flow” of 50 cfs “times” a “head” of 12′ divided by 11.8. 50 X 12 = 600. 600/11.8 = 50.8 kilowatts. To state it another way, 50.8 kilowatts/.746 gives you 68 horsepower. We should assume an efficiency of 90%, so our hypothetical wheel will produce 61 horsepower or 45 kilowatts.

These calculations apply to “any” overshot waterwheel. The only thing that changes among the various designs is the speed or dimensions. Materials should always be a good grade of steel. A36 or B36 works very well. 20 gauge or thicker is good. We always use 1/8″ and ours have withstood direct hits by ice flows of more than a ton. If you use “corten”, a weathering steel, it will not need painting and will acquire a reddish color that resembles wood.

Never use wood

Staticly balance the wheel before installation. No matter how tempting, never use wood. It rots and holds water unevenly. This unbalances the wheel and makes it unsuitable for any use except grinding grain. Be very accurate in all your measurements, especially those concerning “flow” and “head”. If they are wrong, everything is wrong.

I recommend oil-impregnated wood bearing. They can be obtained from the POBCO Bearing Company of Worcester, MA. Waterwheels turn too slowly for ball or sleeve bearings. They cannot maintain a uniform lubricant field. This tends to ruin the bearing quickly. The wood bearings have a “wick” action that maintains uniform lubricant.

(Rudy Behrens owns the FITZ Waterwheel Company. 118 Sycamore Ct., Collegeville, PA 19426, Phone: (215) 489-6256.)

Hi i am having trouble working out the cuvature needed for my overshot waterwheel i am designing as part of my project. Can you please help. the head in my system is 3m and the wheel is 2.6 diameter.

thanks