Page Not Found

Sorry! The page you were looking for is no longer available or the link has expired. If you were looking for a specific product, you can search our store.

While you’re here, take a look through some of our great articles!

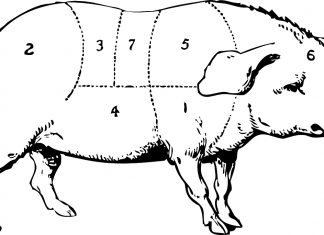

Slaughtering and Butchering

By Dynah Geissal

Issue #23 • September/October, 1993

Fall is butchering time, a period of joy in the harvest of the year's work and of sadness...

A Small Space Yields a Big Crop of Garlic

By Howard Tuckey

Issue #131 • September/October, 2011

In less than an hour last fall, I tilled up a 4x8 foot garden bed and planted 250...

The $1 Garden

By Jonathan Nunan

Issue #122 • March/April, 2010

The dollar garden is simple in concept: buy as many seeds as you can for one dollar and...

Put Your Garden to Bed for the Winter

By Jackie Clay

Issue #95 • September/October, 2005

During the crispy fall afternoons, we listen often and intently to the weather forecasts. "It's going to be...

By John Silveira

Issue #29 • September/October, 1994

(This is a four-part series. Click the links to navigate to parts one, two, three, and four.)

It was the best of times, it was the worst of times...wait a minute, it was the worst of times. I was getting ready to head for...

We the People of the United States, in Order to form a more perfect Union, establish Justice, insure domestic Tranquility, provide for the common defence, promote the general Welfare, and secure the Blessings of Liberty to ourselves and our Posterity, do ordain and establish this Constitution for the United...

By John Silveira

Issue #31 • January/February, 1995

"What were you listening to when I got to your house? Sounded nice. I don't think I've ever heard it before."

O.E. MacDougal looked at me from across the table. He's the poker playing friend of Dave Duffy, the fellow who publishes this magazine....