|

|

| Issue #59 • September/October, 1999 |

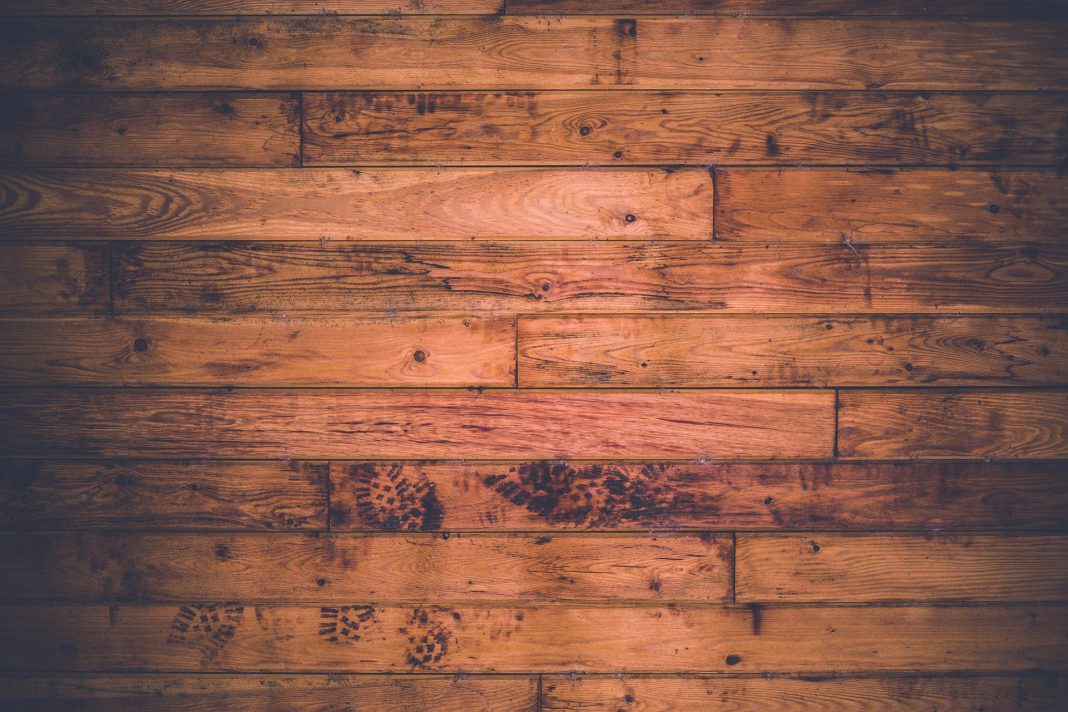

Several months ago we decided we did not want to install a traditional bedroom floor of plywood and carpet. We had several reasons, but the major ones were that I am not one of the great fans of plywood floors and that I also dislike most carpeted floors because, with advancing age, I am also advancing in the number of materials to which I am allergic.

We decided to buy oak flooring and install it, but we modified our plans when we visited our building supply store and learned the price of the oak. On the basis of those prices, I figured I could pay off the national debt about as easily as I could buy the flooring.

For the entire work we wanted to do, we would have paid close to $3,500 for the oak flooring and the nails.

To clean off old stains or varnishes, use a planer set so that the blades barely touch the wood.

So we modified our stance and decided to take up some old oak flooring in a house near us. The oak, we were told, was ours for the taking. The house was going to be demolished and we could have whatever we wished.

So we set to work, and when we were through we had invested several hours of fairly hard work. But we were able to floor not one but three rooms, and there is still oak remaining, if we can get to it while the old house is still standing.

Here’s the bottom line: we removed the old flooring, cleaned and planed it lightly, and re-installed it in the three rooms, all at a total cost of $5.

Now, if you want to repeat what we did, there are several basic steps, the most obvious of which is to find a house with the flooring you want and can get at a premium price. In our case, we had seen the old house standing empty for several years and it was obvious that the structure was too far gone to ever be repaired. The owner had made it public that he would cheerfully give anything inside the house to anyone who would remove it and at the same time agree to four basic requests.

When the wood is planed, you can coat it with a sealer such as polyurethane stain. Let it dry for several hours, preferably overnight, before you install it.

First, whoever took materials from the house was asked not to damage other materials so that others could not use them. By this it was understood that if you don’t need the

paneling, you should not rip it off the walls and ruin it in order to get to

what you wanted.

Second, you were to leave the place as clean as possible. That is, you were not expected to leave boards with nails sticking up so that others might be injured.

And you were not to smash windows that you could not raise because they were stuck. You were not to litter the yard or in any way deface the shrubs and flowers that still grew

in the area.

Finally, you had to agree that you would not hold the owner legally responsible for any injuries you

sustained while you were working

on his premises.

Finding a house

If you have not found an ideal house, go looking for one. Ride around the countryside. When you notice a house that is obviously vacant, and has been for months, even years, inquire as to who owns the house, then seek out the owner and ask about giving you his permission to salvage materials.

If you see a sign in front of a house you might want to pause and look closer. If the sign says something like, “Future Home of Podunk Burgers,” you know the house will not be used for the new diner and common sense says that the owner might be delighted to have someone take away part, or all, of the house.

Notice the building paper under the new floor. This paper will keep the floor from squeakingor it will at least help to do so. When you install each piece of end-matched oak flooring, tap one end gently to get the best possible fit. To keep from damaging the edge of the wood, you can place a scrap piece of oak flooring against the board you just installed, and hammer against that.

You might see a church in disrepair, or a civic building, or a school house, or gymnasium. Read newspapers

for notices of the demolition of

local buildings.

Salvaging

When you have found the house, you will need several pieces of equipment, most notably a pickup truck in which to haul your flooring or other treasures. You will also need a crowbar or prybar, and a hammer with claws.

To take up the flooring, you should remove it exactly opposite from the way it was installed. The flooring is in all probability tongue and groove, which means that only one side of each piece was nailed. The first piece was installed with the groove side against the wall so that the flooring could be nailed through the tongue on the outside edge. All subsequent sections of flooring will have been installed in the same manner.

Your first job is to determine where the flooring started and where it ended. You will start where it ended and work your way back to where it started, otherwise, you will destroy too much of the valuable oak flooring.

Your first step, particularly in an older house, is to remove the molding, then the baseboards. When the

baseboards are out of the way,

you can usually see the groove protruding against the wallor at least

close to the wall.

Use a handsaw when cutting the oak in order to prevent end-splintering.

No matter how careful you are, you may have to damage the first section of the flooring. Start by inserting the claws of the crowbar between the wall and the flooring. Let the claws reach into the crack until you get a good leverage point, then raise the other end of the crowbar until the back side of the flooring starts to break free.

Now slip another crowbar into the same basic area, but a foot or two away, and pry gently with both of the crowbars. As you make more and more progress, work your way down the section of flooring until it pops free. If it breaks, you may be able to cut the piece and use it later. Save everything. You don’t know when you will need a short piece, especially in the closets or hidden areas.

If there are two or three of you working, let one person start to remove the nails that once held the flooring. Keep a gallon bucket

or something similar handy to

contain the nails. Most of the time, cut nails are used to install flooring and you can use these same nails when you reinstall the oak sections.

Continue to work your way across the room taking up each piece slowly and carefully. When you have removed two or three rows of flooring, you can see where the pieces are nailed and, if you insert the hammer or crowbar claws near the nails, you can pop the flooring loose easily. If you have trouble getting the crowbar claws under the oak flooring, use a hammer to hit the back of the crowbar and drive the claws under the section.

After removing the nails, stack the flooring, and be sure that none of the sections are under stress. When you haul it to your house, stack it again in a smooth, even manner. Be sure it will be protected from moisture and other damage.

Installing your floor

Before you think of installing the flooring, you may want to sand or plane the wood lightly to remove all old stains or paints applied ages ago. In our case, we own a small portable planer.

Fitting the oak flooring across a door opening requires patience and care.

I set the planer blades so they barely made contact with the flooring, but deep enough to cut away all of the old stains. It takes only two or three seconds to plane an eight-foot section of flooring and it comes out of the planer looking like new. You can plane enough wood for a full floor within

an hour or two.

You may at this point worry about the damage the old stain will do to your planer blades. And you are right. You will dull the blades after an hour or two of work. What then? In my case, I take the blades out, run them on a bench grinder for two seconds, and put them back in.

You could build a case for buying a planer just for the flooring. Even if you spend $400 for it, when you are finished with the work you still have the planer. We use ours so often, I wonder how we ever did without it.

When you are ready to install the flooring, go over the floor first to be sure that there are no pieces of debris, no nail heads sticking up, or other problems. You may want to put down a layer of building paper before you start installing flooring. It is useful in preventing squeaky boards. Lay a strip of paper and start putting down flooring. Don’t cover the entire floor with building paper; if you do, you will rip and tear it to shreds before you finish the room. Lay the paper as you go.

It is a good idea to place a square in the corners of the new room just to be certain that your corners are square. If they are not, you will need to make adjustments somewhere. More about that later.

Start by pushing the first section of flooring against the wall, the groove side toward the wall. See if the section fits flush against the wall. If the old flooring is bowed or warped, you

may need to set it aside and try another. You may as well get off to

a good start.

When you find a good length of flooring, drive the cut nails into the tongue. Hold the nail so that it is at about a 45° angle to the tongue and the top surface of the oak. If the oak is extremely old, you may need to drill a small pilot hole to keep from splitting the tongue. You can even use the holes that are already in the oak. Try them to see if they work well and offer a good hold.

When the nail head is close to the wood, stop hammering and use a punch to sink the nail the rest of the way. One easy way is to lay the punch across the top of the nail head, then strike the side of the punch with the hammer until the head of the nail is flush with the surface of the wood

at the tongue.

You will find that much older oak flooring is end-matched, which means that you can fit the ends together as if they were pieces in a jigsaw puzzle. The two ends join neatly, perfectly, and soundly.

It is a good idea to lay all of the

sections in stacks that are of similar lengths. We used masking tape

with marks on each section to indicate length. By using the lengths wisely, you can cut waste down to a minimum.

Use the best pieces where they will show off the room to the best advantage. Save the less attractive wood for closets or other spaces that will not be seen readily. However, most of

the wood will be of high quality and this selection process will not be

a problem.

Some sections of flooring will have warped, no matter how very careful you have been. When you encounter pieces such as the one shown here, you can nail a pry block near the wood and use a crowbar to pry the wood into a good fit then nail it while it is in its exact position.

Do not let sections end at the same place. If your room is 18 feet across and if you have flooring lengths of 8 and 10 feet, the simple thing to do is use the 10-foot section first in one course of flooring and the 8-foot section next. On the next course start with the 8-foot section and finish with the 10-foot section. If you have or must use short lengths, try to keep these for use at the ends rather than in the middle of the room.

When you come to a length of flooring that is hopelessly bowed, but you need it anyhow, you can align it by doing the following. Lay the section in position. If it fits well at any point, nail it at that point. Where the bow starts, move out a few inches and nail a short piece of 2 x 4 to the plywood floor. Next, place another short length of 2 x 4 against the floor and also against the flooring. Then put the tip of the crowbar between the two blocks of wood and pry against the flooring until the flooring fits snugly. Hold

the flooring in position while you

drive two or three nails to be sure it

stays in place. You can straighten out a four- or five-inch bow this way. Even if the fit is nearly perfect, keep prying until the fit is exact.

Do not use the crowbar against the oak flooring itself. You will mar the surface of the wood.

When you reach the end of a course, measure the length of the remaining distance then cut your final section slightly shorter than the needed length. Many home-repair people try for an exact fit. But why? You will cover the slight crack with molding or baseboard.

When you come to the end of the room, you may need to rip a length of flooring by using a circular saw. Here, again, do not try for an exact fit. When the piece is cut, tilt it slightly so the groove starts over the tongue. You may need to lay a piece of scrap wood over the final flooring and hit the scrap wood with a hammer to drive the final piece into place.

If you have an especially difficult fit, you may want to turn the flooring over and cut or chip off the bottom side of the groove so that the flooring fits easily into place.

Your final (and optional) job is to apply a coat or two of polyurethane sealer and protector onto the oak. If you don’t want to do this, the floor will remain shiny and bright for months to come. On the other hand, if you want to put a dozen coats onto the wood, no harm is done and you have more and more protection.

I lied. The final job is to stand in the doorway and look at the shiny floor and think of how little it cost to have such a beautiful oak floor.