| Issue #65 • September/October, 2000 |

(Rob Harlan is a general and solar contractor with 25 years of experience with solar water heating systems in Mendocino County, California. Rob primarily designs and installs photovoltaic systems today.)

MH: Rob, will you give a brief history of the last 30 years of solar-water heating system design and implementation?

Rob: Solar-water heating systems got a real boost in the 1970s when tax credits were offered by state and federal programs to help folks make the investment. These systems were intended primarily for domestic hot water, i.e., showers, dishwashing, cooking, and clotheswashing. They were also popular for heating the water in pools and hot tubs. This movement slowed to a snail’s pace when the tax credits ran out.

MH: As I recall, a lot of manufacturers also disappeared when the tax credits went away. Of course, some of these systems were poorly designed, used cheap components, or lacked adequate protection against freezing, overheating, or corrosion. I know that you’ve upgraded solar water heating systems over the years, or older systems from homes and businesses in favor of newer designs. What’s your experience of the design and hardware from 30 years ago?

Rob: Some designs were indeed flawedpoorly implemented, overly complex, or incorporating untested ideas. Still, even good designs require some maintenance. The lack of knowledgeable service personnel and parts crippled some systems. The solar collectors from these systems are actually pretty rugged and often find their way back into new installations sold “as is” or used. Today’s manufacturers of solar water heating systems and components have benefited from the lessons learned long ago. Things are back to a steady pace, with a variety of manufactured system types. Most offer good reliability, are warranted, and generally follow time-tested designs.

MH: There are a few parts that are basic to most solar water heating systems (Fig. 2): collector(s), storage tank, heat transfer medium, and interconnecting plumbing. The collector intercepts the sun’s rays and converts it into heat which is transferred to the storage tank using a fluid such as water or antifreeze. An expansion tank is used in closed systems to accommodate the slight changes in volume that result when water or antifreeze is heated and expands. If glycol (a non-toxic antifreeze liquid) is used, a heat exchanger is needed to transfer the heat from the collector to the water that will exit the faucet. A T&P (temperature and pressure) relief valve is a common safety device found at the top of water heaters. If the water gets hotter than it should or the system builds up too much pressure, this valve will open, releasing water until the temperature or pressure drops to safer levels. The simplest control system disables the backup heating system (gas or electricity) during daylight hours, giving the sun a chance to heat all of the water in the storage tank.

Rob: Andon active systems, a controller turns a pump on and off as solar heat is available. Let’s define a few terms used to describe these systemsactive vs passive, open vs closed. An active system is one that uses pumps to move the heat about. A passive system is one that contains no pumps, relying instead on natural convection, conduction, or radiation to move heat. An open system means the water circulating through the collector is the same water you’ll use in a shower (Fig. 3). A closed system circulates the separate heated fluid from the collector through a small loop that includes a heat exchanger, usually located in the storage tank (Fig. 4).

MH: I understand why some people choose passive over active designs. Pumps, controls, relays, and motorized valves all require electricity. Electricity is a very specialized and sophisticated form of energy. Folks who live in the country beyond the grid know what a luxury electricity is. We know it’s a luxury because it’s expensive to make. And very expensive to make a lot of it. It’s a shock for folks who have lived most of their life with utility power to move beyond the grid. A passive solar heating design for making domestic hot water or warming a home requires little or no electricity to operate. Fewer parts, less to go wrong, less to take bites out of your pocketbook. With passive, it’s all in the design. Considered experimental in the 1970s, passive solar heating has proven itself worldwide in a wide range of climates. Speaking of climates, why would someone choose a closed system over an open one?

Rob: Freezing protection. If the water in the collector freezes, it will burst a tube or header. It’s messy, it dumps your hot water, and it must be repaired. You don’t have to live in a place with hard freezes. Water in a collector open to a clear sky can actually freeze when the ambient air temperature is as high as 40 degrees F. This condition is called night sky radiation.

MH: Incidently, there are two reasons why water that freezes will burst its plastic, metal, glass, or stone container. Actually, they are simply properties of water. One, water is virtually incompressible. Two, water expands slightly as it changes from a liquid to a solid. Water immobile inside a small tube or pipe and exposed to a freeze, then, will begin to expand as it becomes ice. Unable to compress itself, it makes a bigger volume by breaking whatever contains it.

Rob: True. It’s actually the different strategies used to combat the potential of freezing that define the major types of systems and their relative complexity. I’ve categorized existing systems into seven types: integral collector/storage, thermosiphon, three-season, drain-back, drain-down, re-circulation, and active closed-loop.

MH: Will you describe them all, first generally and then assess their merits and liabilities from your own experience?

Rob: I would be glad to. I must say first that my experience with solar hot water is limited to my service area (coastal northern California) which is a fairly benign climate with occasional light freezes. I ask your readers to keep this in mind as I speak of various systems.

1. The integral collector/storage is the simplest and historically oldest type of solar water heating system. Paint a tank black, put it in a big crate, insulate it on all sides except the one covered by glass or plastic, and point it at the sun. Water in the tank is heated directly by the sun and stored in the same unit. In the trade, this is also know as a breadbox-type system. An example of a manufactured unit of this type is the Servamatic™. Produced in the 1970s, many are still operational today. The same principle can be seen in today’s ProgressiveTube™ unit (Fig. 5). These are also in-line units, positioned between the well and the shower. You get as much hot water as they collect and store.

MH: This is a popular design in homebuilt units, too. Simple, cheap, and often made with recycled materials. I once took a shower at a ranch I was visiting from water heated in a long thin 20-gallon tank inside an old, big refrigerator with a transparent cover pointed south. I had a long, hot shower in the cold night air. Good experience.

Rob: I have very rarely had to service an integral collector/storage type system, which is a testament of their durability.

2. The thermosiphon system is another solar water heating method (Fig. 6). Sunlight strikes tubes and fins inside a collector box through which water or glycol is circulating. The inlet and outlet of the collector are plumbed, respectively, to the inlet and outlet of the storage tank. If we were talking about electricity and polarity, we’d say the collector is in parallel with the storage tank. Still, it forms a loop. The heated fluid moves from the collector to the storage tank and back to the collector through a process called thermosiphon. This is a natural convective action. If you plumbed this as an open system, the storage tank could be your own water heater.

MH: I’d like to elaborate on a few things you’ve said. Thermosiphon results when water heated in the collector expands and rises, pushing cooler water in the rest of the loop into flowing. Cooler water is pushed out of the bottom of the tank and into the bottom of the collector. Once circulation starts, the process continues unabated all day.

Just as the sun heats the water in the collector, the night sky can cool a collector, causing reverse flow. Think about it. Water in the collector is cooled by nighttime stagnation. Cold water is heavier and sinks, pushing the entire loop into reverse flow, moving warmer water from the tank to the collector which is, in turn, cooled. This will quickly give away some of that hard-earned hot water.

The easiest way to avoid this is by positioning the bottom of the tank above the top of the collector (Fig. 6). This is a physics trick that will prevent reverse flow. Sometimes it’s not possible to elevate the tank above your collector. Thermosiphon will work even if the tank is positioned level with or even somewhat below the collector. In this case, the addition of a check valve will prevent reverse flow (Fig. 7). Avoid the standard pressure-type check valve. It’s too resistive to thermosiphon flow. Instead, use a gravity-type check valve. Angle it in with the plumbing for minimal pressure to open, minimum backflow to close.

The solar collector itself is something of a mystery to many folks and I get many questions about it. A common configuration uses a box, a grid of water tubes, insulation, and glass or plastic glazing (Fig. 8). The box is a large shallow pan, with designs varying smaller and larger in width and length than a standard sheet of 4×8-foot plywood and 4-6 inches in depth. Manufactured designs use stainless steel or aluminum for the boxes but most homebuilt units use plywood. If properly glued and screwed and sealed against weather, they are tough.

Homebuilt designs start with a 4×8-foot sheet of plywood ½ or ¾-inch thick. From it (or another sheet of plywood) cut two 4-6 inch strips from each dimension, supplying the material for the box’s four sides. Large diameter (1½-inch to 2-inch) copper header tubes at the top and bottom of the collector are oriented horizontally and plumbed together with smaller vertical tubes (i.e., ½-inch tubing) spaced 3-6 inches apart. Tin or copper fins or sheet is mechanically and thermally connected in a variety of methods to the tubes. Tubes and fins are blackened with paint or through electrochemical processes. Fittings are added for connection to external plumbing or other collectors. Sheet foam insulation is added behind and to all sides of this assembly when it is mounted in the box.

Glass, greenhouse fiberglass, or some other translucent plastic glazing is added to complete the unit. Glass is available in a range of sizes, particularly if it’s recycled. UV (ultraviolet)-resistant fiberglass is available at local hardware stores in several widths. Don’t burden yourself with plastics that will crystallize in one or two seasons from exposure to the ultraviolet rays of the sun. Select your glazing first. The best economy results when the box is sized to the glass you already have or can get.

Rob: I am reluctant to endorse building one’s own collectors, given the availability of used collectors. If you do build your own, don’t use aluminum absorber plates. They will react adversely with copper tubes. Also, it is best to silver solder any joints within the collector. The collector goes through large temperature swings. This is hard on standard solder joints.

MH: Indeed, the experience of building one’s own collector usually brings about an appreciation for how inexpensive used collectors really are. So, my recommendation to the enthusiastic do-it-yourselfer is: don’t commit to building a whole bunch of collectors without first building one.

Rob: A few more comments on thermosiphoning. If you thermosiphon with water and live in a climate with freezing temperatures, your collector will freeze and burst. Sometimes passive freeze protection valves are installed in such systems. Often called Dole valves, these are designed to open at a preset temperature, 34°F or 45°F. They drip water to create a flow through the collector and, in this way, prevent freezing. In my experience, these valves are not reliable, so I cannot recommend them.

MH: I haven’t used Dole valves personally but I know that some people in the area, including Stephen Heckeroth, do trust and use them. However, it is also my understanding that Dole valves must be periodically inspected and cleaned. If you’re the type of person who isn’t good at regular maintenance, you’d be better off selecting a different system.

Rob: If you live in a climate zone without freezing temperatures, an open thermosiphon system will work well. If not, I still recommend using glycol and a heat exchanger for the thermosiphon loop.

3. The three-season system is another tactic for handling freezing. The idea is to use the solar water heating system for three seasons and drain it for the fourth. It can be a thermosiphon or pumped system and assumes the owner will use another source of energy for heating the water.

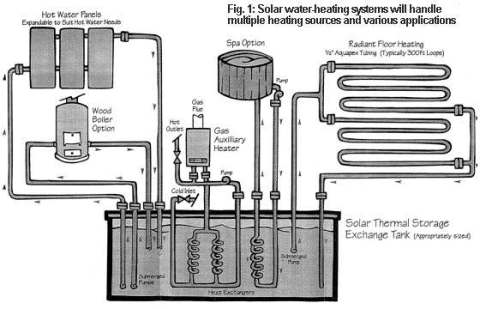

4. Drain-back is another type of solar water heating system (Fig. 1). This drains the water in the panels into a tank when there’s no heat available from the sun. The panels are empty of water, then, and cannot freeze. A non-pressurized tank is used to capture this water, and a pump refills the panels when the sun’s warmth is detected.

5. Drain-down is a variation of the drain-back solar water heating system. Here the water is dumped onto the ground. This is a fairly common design, particularly in older systems. It uses a Sunspool™ valve to fill the panels for operation. The same valve, when it reaches a lower temperature, opens to dump the water that’s in the panels onto the ground.

6. Another type of solar water heating system is re-circulation. This method of freeze protection activates a pump to circulate a little bit of hot water from the storage tank back into panels when low ambient temperatures are experienced.

7. Active closed-loop is the final type of solar water heating system on my list (Fig. 9). This design uses any fluid in the collector-to-storage loop that won’t freeze at the low temperatures the system is likely to experience. The heat gathered in the collector is transferred to the water in the storage tank via a heat exchanger. What fluids won’t freeze? I’ve seen systems use glycol, silicon oil, and methanol. Automotive anti-freeze might seem a good candidate, but it’s poisonous. The most popular heat transfer medium is polypropolene glycol, a food-grade dough extender used in the baking industry. It costs about $20 a gallon and is mixed with water. A 10% mixture will protect the collectors down to 20-25°F. The ratio of glycol to water is increased for lower temperatures. I use a 50/50 mixture in my service area.

There’s a lot to be said for using pure water in a solar water heating system. Water is non-toxic, widely available, and cheap. Also, it is the most efficient heat transfer fluid and does not degrade in use. Glycol is also non-toxic but it does break down over time. Exposed to high temperatures, it becomes acidic and will eventually begin to eat your plumbing. So, glycol needs to be checked periodically. I use litmus paper to check its pH. It’s a fairly simple matter to refresh the system with a new glycol-water mix.

Incidentally, there are some types of systems that don’t really fit into any of these seven categories.

The popular Copper-Cricket™ is one example. This system used a 20% methanol mixture under a vacuum to actually “pump” heated fluid down to a storage tank without a pump. It operates on the same principle demonstrated in a coffee percolator to transfer heat. Another is the Sun™-family of solar thermal collectors. These use columns of evacuated tubes to collect and transfer heat.

There’s more basic stuff, too. Some folks just spiral plastic pipe on the ground to pre-heat the water that goes into their standard water heater. It works but if a sudden freeze doesn’t ruin it, long term exposure of the plastic pipe to sunlight will.

MH: The softer, more flexible black plastic tubing you’re referring to is identified as PE, or polyethylene tubing. Ultraviolet radiation from the sun breaks down any kind of plastic, disintegrating the bonds of the polymers and turning the plastic brittle. The black tubing sold in rolls is neither designed to work in direct sunlight nor withstand elevated temperatures. Hot water, particularly with soft water, will leach stabilizers and joint cement from the tubing, too. This is great for showers but you don’t want to drink this water or cook with it.

Rob: If there’s one thing I’ve observed, it’s that most folks who build their own system try to re-invent the wheel, and their designs sometimes reflect a lack of understanding of the basic principles. With good plans, most people could build a good system. Still, many folks don’t want to do it themselves.

MH: I prefer doing my own system yet I have to admit that I have often overrated my ability to be there when the system really needed me. Rob, will you go back through the list of systems and give us your thoughts on the advantages and disadvantages of each type?

Rob: The integral collector/storage system has the advantages of low cost, simplicity, and the lack of pumps or controls. Even homebuilt versions are long-lasting. The tank has enough thermal mass to avoid freezing except in hard-freeze areas. The disadvantages? This design is relatively inefficient and the water often doesn’t reach a very high temperature because the glass-to-mass ratio is small in a breadbox-type system. Heat losses from the collector are high at night, so there is definitely a time of optimal use of the hot water produced, usually afternoons and evenings. The collector/tank combination is heavy, too. Filled, it may reach 650 pounds and tax an unreinforced roof.

The newer ProgressiveTube™ collectors of this type (Fig. 5) are simple and use 4-inch copper tubes and fins with special “selective” surfaces. They extract more of the sun’s energy than blackened surfaces and resist re-radiation of this energy at night. I recommend ProgressiveTube™ systems for my climate zone.

The thermosiphon system has the advantages of simplicity and good efficiency. It doesn’t require electricity and is therefore unaffected by a utility blackout. One disadvantage of thermosiphon flow is that the plumbing must follow strict guidelinesbigger tubing, gentle turns, no low spots, and no restrictive valvesto ensure a smooth, unrestricted flow. An air pocket at a high spot or a large bubble somewhere in the system will stop thermosiphon flow.

MH: I’d like to add to your comments on thermosiphon. I’ve found this to be a neat, natural way to move heat from a collector to storage or use. Water pumping in rural locations can eat a big portion of anybody’s energy pie. Any process that will pump water and the heat it contains through a pipe without external power is a blessing. Butthermosiphon will not tolerate poor planning or a sloppy installation. It wants free, unrestricted motion. Even the check valve must be a gravity-type rather than a pressure-type to avoid becoming restrictive.

Tests have shown that thermosiphon doesn’t start until the collector reaches a critical temperature (Fig.10). Flow commences rapidly, slowing to a more constant rate. A bubble big enough to block a tube will stop flow immediately. The collectors can get hot enough to blow a T&P valve and still no flow. It’s exciting to see water and steam shooting up into the air but, alas, not very productive. Steeply-pitched pipes will ensure a good flow.

I know that in-line, centrifugal-type pumps are used in radiant floor systems to periodically purge the thermosiphon loops of air bubbles. Theoretically, thermosiphon can push water through the pump when it’s off. The pump has another use. It enables the owner to pump more heat into the floor from storage at night.

I added a small purge-pump to one thermosiphon system in the 1970s. I wanted to use primarily thermosiphon but the system included existing plumbingnaturally inaccessibleand the thermosiphon flow kept getting blocked with bubbles. I added a small 12-volt pump in parallel with the check valve (Fig. 11) to occasionally purge the system with a faster flow rate. I used a positive-displacement type to avoid any flow of fluid through the pump when it was off.

Rob: I’ll go on. The three-season system has the advantages of using the existing water heater as a backup, being inexpensive, and requiring only a small pump. The disadvantages are that it is susceptible to freezing and depends on the owner being there to drain it when the weather is cold. There is an overall limit to the size of this system when it’s plumbed to a water heater of a specific capacity.

The drain-back system (Fig. 1) is relatively simple, versatile, and freeze-proof. The tank used in this type of system is long-lasting and there is little maintenance required. During a blackout (or other loss of electricity to the system), the panels are empty and will not overheat. It’s even possible to set up the system so that thermosiphon will get the heat to your water heater. The disadvantages are most evident in off-grid systems, where the energy used in pumping is relatively high. This is because the pump must be sized to fill the collectors daily rather than just circulate water through them. As well, the tank must be located below the panels so that the water that is drained back will have a place to go. This is my favorite choice of a system for freezing climates.

The drain-down system has the merits of high efficiency and is a freeze-proof system. It uses a small pump with small energy use. The disadvantages? Lots of expensive parts, including a complex controller, and the need for periodic inspection and maintenance. However, in any application with a limited supply of water, the daily dumping of water from the collectors onto the ground will be an issue.

The re-circulation system has the advantage of using a standard hot water heater to double as the storage tank. And it’s freeze-proof if the system is small. It has the disadvantage of wasting a lot of energy. If it’s really cold, the backup heating system, say an electric element, has to heat water that is simply being radiated away from the collector at a significant rate.

The active closed-loop system (Fig. 9) is freeze-proof and contains quality components. One disadvantage is that it is complex, meaning it has pumps, valves, and various controls. The tank with heat exchanger is expensive but adds a lot of useful, well-insulated thermal mass to the system. If utility-powered, the pump won’t work during a blackout.

MH: There’s merit to the idea that if the system depends on electricity, the electricity should be generated from the sun, too. If there’s sun for the collectors, there’s sunlight to make electricity to power the pump and move the heat.

In all of these systems, if the collectors overheat, a T&P relief valve will provide protection. There’s a down side with the T&P valve blowing. First, it gives away a lot of hot water since the valve won’t close until both the temperature and pressure fall. And, second, dumping the heat transfer medium can be expensiveif it’s a glycol/water mixture.

I want to thank you, Rob, for turning me onto the fact that a P-type (pressure-only) relief valve is manufactured. I want to use one of these in my next installation. I suspect it will keep the system from dumping all the hot water since it should close as quickly as the pressure is relieved. The pipes in the collector can take heat, but have a tougher time surviving pressure.

Rob: I guess my critique of the advantages and disadvantages of these systems reveals my bias. Generally, I have found with solar hot water, the simpler the better. The simple systems seem to last longer, as a rule.

MH: Bias? I appreciate your review and advice. I’ve learned a lot. Will you describe how you size a system to the application and match components with each other?

Rob: Almost every hot water system has a backup. I design for 70% solar usage. A four-person family is a good standard. Two 4×8-foot collectors will supply the hot water needs of four people. The tank should be sized to the array. In my climate, I’ve found that 1.8 gallons of fluid per square foot of collector is a good ratio. So, two collectors of 32 square feet each will require a storage tank of 115-gallon capacity. For radiant floors, I’ve found that the collector area should be about 10% of the floor area. The same two 4×8-foot collectors, then, will handle about 650 square feet of radiant floor.

MH: What’s the average cost of water heating with electricity, propane, and natural gas for a 4-person family?

Rob: Yes. Using electricity at 12¢ per kWh, the cost of water heating is about $46 month or $551 annually. Propane at $1.41 per gallon costs about $26 a month or $307 per year. Natural gas and fuel oil are less, as is electricity in other parts of the country. Of course, when a solar water heating system is installed and has returned the investment, the energy from it thereafter is free.

MH: Will you give me an idea of how long it will take to pay off the cost of several of these systems based on these rates?

Rob: I have that information, too. First, let me say that these figures do not include the cost of maintenance, the rise in the cost of utility electricity, the lost interest on the investment, and no tax on the savings. In my experience, these balance each other out.

A new integral collector/storage system using the ProgressiveTube™ design will cost about $2,500 parts and labor to install. After 7.3 years, the system cost will equal the cost of electricity to heat the same water during that time. With propane, it’s about 13 years. If the owner installs the system, the cost is about $1,600. The payback is 4.8 years for the avoided cost of using electricity and 8.7 years if using propane.

A new drain-back system costs $3,500 parts and labor. This is equal to 8.5 years of electricity and 15.2 years for propane for domestic hot water. A system that will heat a hot tub will cost about $4,800. When heated electrically, the payback computes to 7.5 years.

MH: In my experience, folks who install their own solar water heating systems usually begin by putting one collector in a loop to the existing water heater. If you shower in the morning, what’s the conventional method for preventing the water heater from using electricity or propane to reheat this water before the sun gets a chance at the task?

Rob: In an electric heater, it’s easy. A 24-hour timer can be set to lock out the backup heating during daylight hours. The owner can manually override the timer with the flip of a switch during bad weather or unusually high demand. For a propane or natural gas heater, turn the gas valve to the pilot position.

MH: There is a proper way to plumb the solar collector to the standard water heater, too. Today’s water heaters position the cold-water inlet and hot-water outlet at the top of the tank. Cold incoming water to the tank actually drops through a tube inside the water heater which ends just above the bottom of the tank. For thermosiphon flow, this is not a good arrangement; you want the cold water return to the collector to exit directly from the bottom of the tank (Fig. 12). Fortunately, water heaters have a drain valve. There is a way to re-arrange this plumbing (Fig. 13) so that the collector will use this orifice for its thermosiphon loop while you retain the ability to drain the tank.

If someone wanted to assemble their own solar water heating system, what’s a good source of information and parts, beyond the library and internet?

Rob: A wonderfully detailed overview of solar hot water systems, complete with schematics and technical information, is found in the Solar Water and Pool Heating Design and Installation Manual from the Florida Solar Energy Center at (407) 783-6300. Triple A Solar in Albuquerque, NM (800-245-0311) sells used solar-thermal collectors at good rates. Check out local sources of used panels to avoid shipping costs. Six Rivers Solar (816 Broadway, Eureka, CA 95501) at (707) 443-5652 sells a high-quality, rectangular thermal storage tank that integrates the inputs and outputs of collectors, auxiliary heating sources, DHW, radiant floors, and hot tubs (Fig. 1).

Rob Harlan, Mendocino Solar Services, 42451 Road 409, Mendocino, CA 95460

Michael Hackleman, PO Box 327, Willits, CA 95490. E-mail: mhackleman@saber.net